FILTER PRESS

Filter press is one of the earliest equipment used for sludge dewatering. It works on the principle that the solid phase accumulates in the spaces between the filter press plates and the liquid phase is filtered off through filter cloth. It provides the highest dewatering efficiency among the equivalent technologies with its solid content reaching 30-35%. It is widely used because of its low CAPEX and OPEX. A lot of models such as manual, fully automatic etc. are available depending on the user request.

Application Fields:

- WASTE SLUDGE formed in wastewater treatment facilities is dewatered by filter press. The storage, transport and disposal of waste sludge is facilitated; expenses relate to these operations are reduced.

- The wastewater lime formed because of production activities in ACETYLENE PRODUCTION FACILITY is dewatered in the filter press. Ex-proof equipment is available for that application.

- High amount of water is used for vehicle and floor washing in the CONCRETE BATCHING PLANT. To reduce this high-water consumption, wastewater is collected then reused after filtration through filter press. Filter press is preferred because of its high dewatering performance and easy operation. Not only water consumption but also transport and storage costs for sludge disposal decrease, facilities become cleaner and greener.

- There are huge clarifiers in the COAL WASHING FACILITIES that water upstream is recirculated to the process. Sludge extracted from the bottom of clarifier is dewatered by filter press to be stored regularly in solid form.

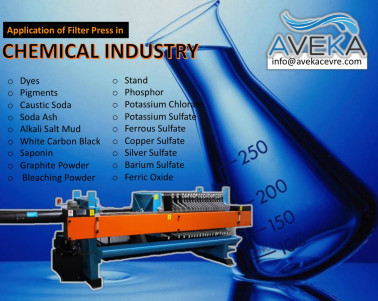

- It is used for suspension filtration in various chemicals production lines (dyes, pigments, caustic soda, soda ash, sodium bisulphite, zinc sulphate, copper sulphate, zinc oxide etc.) in the CHEMICAL INDUSTRY.

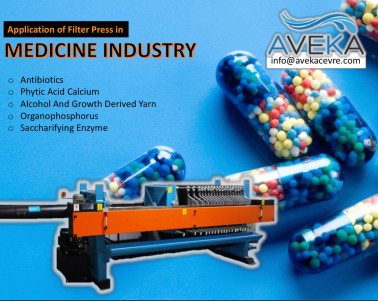

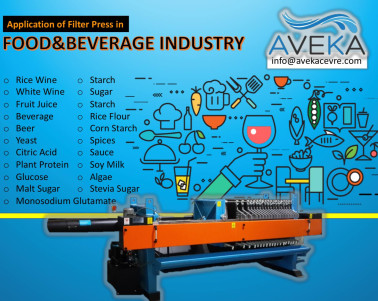

- FOOD: Rice wine, white wine, fruit juice, beverage, beer, yeast, citric acid, plant protein, plant sweet element, glucose, malt sugar, stevia sugar, malt sugar, starch, sugar, starch, rice flour, corn starch, liquid glue, monosodium glutamate, spices, sauce, oral liquid, soy milk, algae. Filter press is used in cold press VEGETABLE OILS FILTRATION (white oil, sesame oil, light oil, glycerine, seeds oil, vegetable oil). Filtration is required to ensure that the resulting oil is bright and free of deposits.

- The particles are filtered out using filter press in the PRODUCTION OF BIODIESEL.

- Filter press is used for filtration of MARBLE CUTTING waters to reuse in the cutting process.

- Filter press is used for dewatering the dough in CERAMIC PRODUCTION.

- CLAY: Old soil, bentonite, activated soil, China clay, electronic ceramic soil.

- It is used for filtration of deposits in the coating baths in METAL COATING facilities.

- It is used for the filtration of gypsum waters and recovery of precious metal from castor oil in METALLURGY (gold, silver, copper, iron, zinc, rare earth powder processing, etc.) industry.